Advantages

Precision

After several years of accumulation of experience in R&D, design and precision manufacturing, We have mastered the core technology of design and manufacturing related to interconnected products and precision structural parts, and have acquired a stable and high-quality customer base, and have a strong competitive advantage in the industry. Precision structural products currently mainly include soft copper bars, hard copper bars, battery boxes, etc. for power batteries.

Since its establishment, We have set up a technology research and development department, and have introduced a group of outstanding technical talents from well-known domestic and foreign enterprises and professional institutions. The R&D personnel hired by the company have rich industry experience in precision connector design, precision mold development, production line automation design, product testing and verification. Since the establishment of the company, it has continuously made technological breakthroughs in connector products, and obtained a number of independent research and development patents and non-patent core technologies. Comprehensive product development to meet the customized requirements of customers to the greatest extent.

-

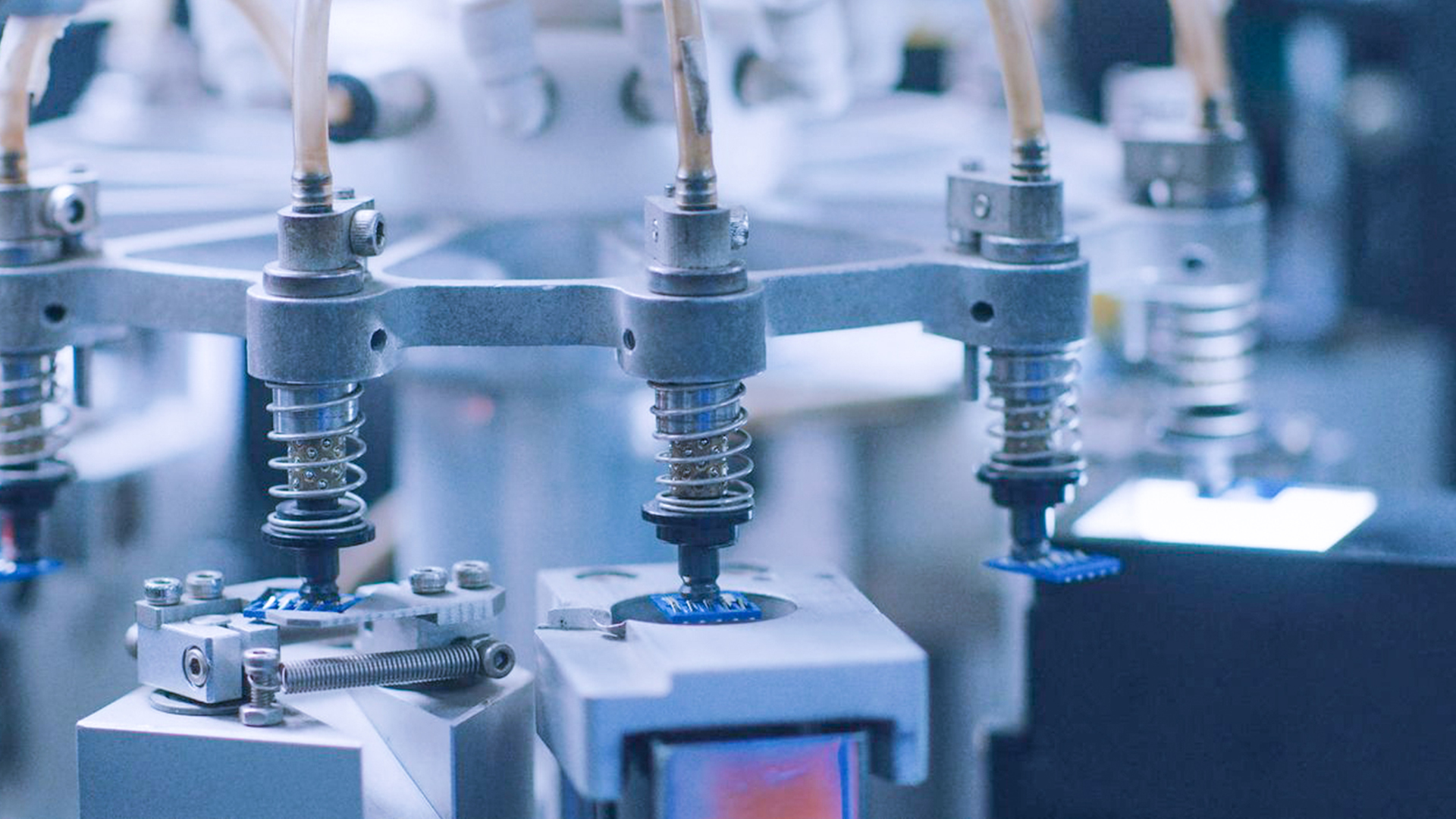

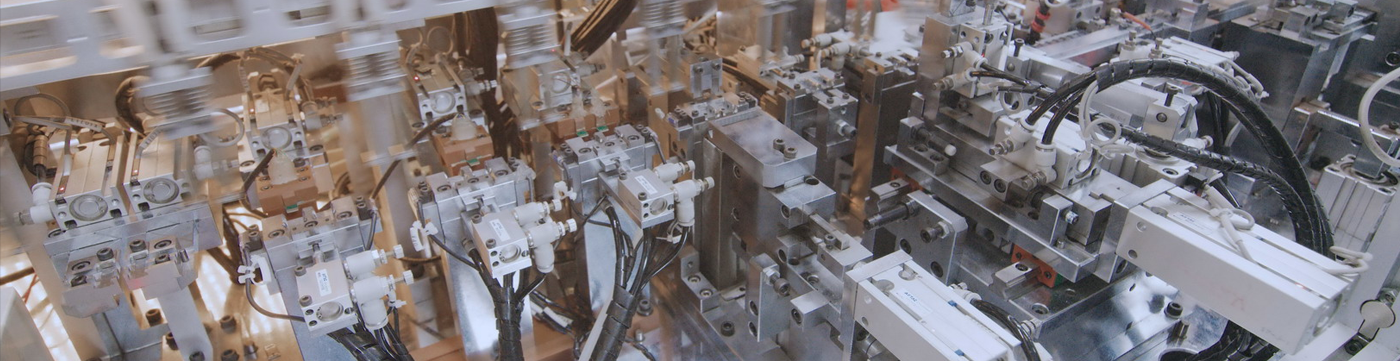

We focus on the design and manufacture of precision interconnect products, and have different types of precision punches, precision injection molding machines, precision molds, precision automation equipment and precision mold processing equipment (accuracy up to 0.002mm), etc. Through more than ten years of efforts, We hace an efficient, scientific and standard precision manufacturing process has been gradually established.

-

Precision mold is the "mother of industry" of precision manufacturing. We have experienced mold developers, and have established a complete mold design, parts processing, mold assembly and test mold operation process.

-

We currently have the ability to independently develop and design various types of molds, of which the continuous mold can produce up to 128 pieces per mold. Our precision metal molds have reached the leading level in the industry in special-shaped deep drawing (the drawing height reaches 80-100 times the material thickness), multi-belt (2 belts/4 belts), and multi-cavity (12 holes). Precision injection molding has a strong competitive advantage in the aspect of in-mold composite insert molding (embedded molding, the minimum plastic wall thickness is 0.05mm, and supports 3 times of molding).

-

Precision automation equipment is an important cornerstone of enterprise transformation and upgrading. We have professional automation structure design and electrical designers, and have established a complete automation design, parts processing, and automatic machine setup.